Test method of transformer comprehensive tester

Release Time : 2017-04-07 View Count : 次CTP-1000A transformer comprehensive tester is a new generation of CT and Pt testing instrument of our company. CTP-1000 series products are based on the testing principle of frequency conversion method, which can complete the comprehensive test of CT and PT on site without voltage regulator, voltage booster and current converter. The output voltage is low, and the safety of the tested equipment and test personnel can be ensured no matter whether there is wrong operation or not. The device adopts high-performance DSP and FPGA, and advanced manufacturing technology to ensure stable and reliable product performance, complete function, high degree of automation, high test efficiency and is in the leading level in China. It is a professional test instrument for transformer in power industry.

The following is a brief introduction to the current transformer test method:

Current transformer test

In the parameter interface, use the mouse to switch the cursor to the type column and select CT as the transformer type

Test wiring

The test wiring steps are as follows:

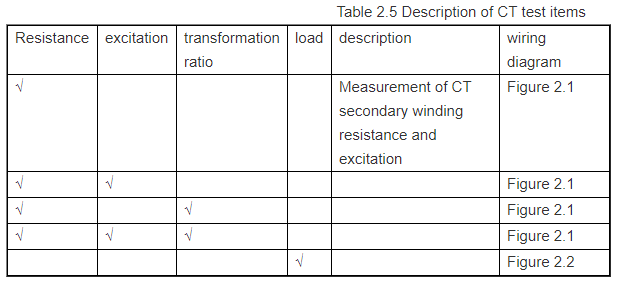

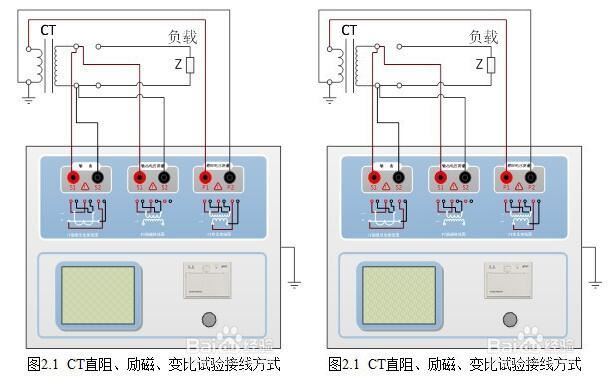

Step 1: according to the description of CT test items described in Table 2.1, conduct wiring according to figure 2.1 or Figure 2.2 (for CT of various structures, refer to the actual wiring mode described in Appendix D).

Table 2.1ct test item description

Step 2: other windings of the same CT are open circuit, the primary side of CT should be grounded, and the equipment should also be grounded.

Step 3: turn on the power and prepare for parameter setting.

Parameter setting

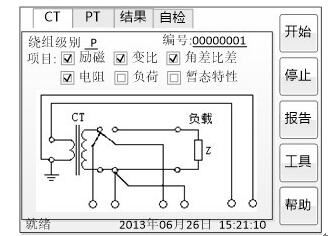

The test parameter setting interface is shown in Figure 2.3.

The parameter setting steps are as follows:

Rotate the mouse to switch the cursor and select the test item to be carried out. When the cursor stays at a certain test item, the screen displays the parameter settings related to the test item; when the cursor leaves the test item, the screen displays the wiring diagram corresponding to the selected test item.

The parameters that can be set are as follows:

(1) Number: input the number of this test, which is convenient for printing, saving, management and searching.

(2) Rated secondary current: the rated current at the secondary side of current transformer, generally 1a and 5A.

(3) Grade: the level of the tested winding. For CT, there are 8 options, such as P, TPY, metering, PR, PX, TPS, TPX, TPZ.

(4) Current temperature: the winding temperature during the test. Generally, the air temperature during the test can be input.

(5) Rated frequency: optional values are: 50 Hz or 60 Hz.

(6) Maximum test current: generally, it can be set as the rated secondary current value. For TPY class CT, it can be set to 2 times of the rated secondary current value. For class P CT, if it is 5p40 and rated secondary current is 1a, then the maximum test current should be set as 5% * 40 * 1A = 2A; if it is 10p15 and rated secondary current is 5a, then the maximum test current should be set as 10% * 15 * 5A = 7.5A.

If you want to see the following results, you need to set the basic parameters accurately (it is recommended that you set them).

(1) Turn ratio error, ratio difference and phase difference

(2) Accurate calculation of limit electromotive force and its corresponding compound error

(3) The measured accurate limit coefficient, instrument safety factor and symmetrical short circuit current multiple are obtained

(4) Measured transient area coefficient, peak instantaneous error and secondary time constant

For different levels of CT, the parameter settings are also different, see table 2.2.

Step 5: select the start button on the right to test.

Note: when the name plate of transformer is lost, please input 0 for primary current and secondary load and the instrument will judge automatically according to national standard and test results.