Manual operation method of generator rotor AC impedance tester

Release Time : 2019-01-24 View Count : 次ZC-401A generator rotor AC impedance tester adopts advanced high-speed microprocessor technology, which has more powerful function, better performance and more convenient use. It has the characteristics of high reliability, easy operation, high precision, small and light. At present, it is at the leading level in China.

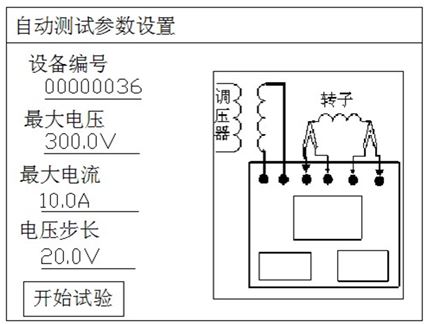

1) Press the direction key to select "automatic test", and then press "OK" to enter the "automatic test parameter setting" interface as shown in Figure 1. The wiring diagram of the test is on the right side of the interface.

Fig. 1 automatic test parameter setting interface

Among them:

Equipment number: it is used to distinguish different equipment, different test properties and times. It’s convenient for searching in historical data and convenient for technical management.

"Voltage step size" refers to the size and range of interval voltage number (5-50v) between each data acquisition when data acquisition of various parameters is conducted based on voltage.

The maximum voltage refers to the maximum voltage value to be tested in the test, with the range of 0-600v. 1.1 times of the set value is the default overvoltage protection action value of the instrument.

The maximum current refers to the maximum current value to be tested in the test, with the range of 0-120A. 1.1 times of the set value is the default over-current protection action value of the instrument.

2) Connect the voltage regulator, the instrument and the measured rotor winding according to the wiring diagram in the interface. A more detailed wiring diagram is provided at the back.

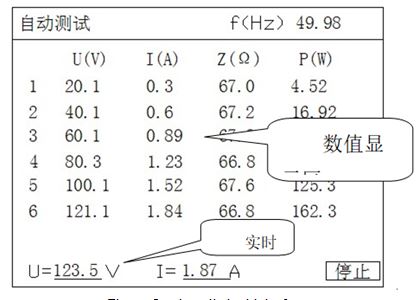

3) Set the above parameters according to the test needs, move the cursor and select "start test" to enter the "automatic test" interface as shown in Figure 2.

Figure 2 automatic test interface

The top part of this interface displays the current voltage frequency, the middle is the main display area, displaying the captured data records, and the bottom part is the real-time value of current voltage and current. In this interface, adjust the voltage regulator, and the instrument will automatically collect and display the measured values of all parameters at each test point. Until the maximum set voltage value is reached, the buzzer of the instrument will give a prompt sound to prompt the completion of data measurement. At this time, the voltage regulator should be quickly returned to zero.

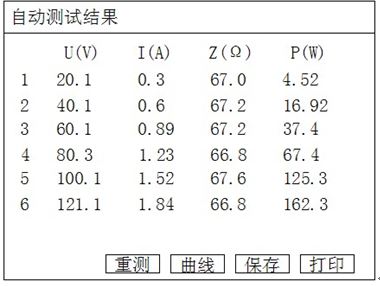

4) After the test, the instrument interface will switch to the "automatic test results" interface as shown in Figure 5.

Figure 3 automatic test result interface

In the current interface, you can traverse the measurement results by pressing the "↑" and "↓" keys on the keyboard. Presses “save" to save the current test results to the memory of the instrument for future reference. Press "print" to print out the current test results through the panel printer. After pressing the "curve" key, the instrument will draw the "voltage current relationship" curve as shown in Figure 6 according to the measured data.